Since 1998, APPL is in the business of Silicone Elastomeric products and also, other Polymeric components which ultimately provide solutions to Fluid Transfers, Sealing, and Contamination controls for Biopharma, Pharma, Medical, Laboratory, Food, Beverages, and Engineering sectors worldwide.

APPL is having ISO Class VII and ISO Class VIII Cleanroom facilities certified with ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 27001:2013, ISO 13485:2016. We also have a BPOG extractables program for our products for regulatory markets worldwide.

The company believes in “Be in business with ethics” and assure Quick Development, Fastest Delivery, Ultimate Quality and also very Competitive Rates.

APPL has world-class manufacturing technology with end-to-end process capabilities to fulfill the needs of customers. which include Extrusion Technology with Laser Controlled system, Automatic Hose Production lines, Plastic Extrusion Lines, Automatic Hydraulic Presses for Elastomers & Polymeric components, Laboratory with R&D Equipment, In-house Tooling & Mould making machinery, Laser Cut Machines, and Online Printing as well as Marking systems on products.

Over the years the Company expanded its capacity of manufacturing by adding a huge facility that provides end-to-end solutions to our clients worldwide. Our products are available across the globe directly and through the distribution networks.

To Become a Global Leader in Inflatable Seals, Pharma Tubing’s and Silicone Rubber Implants.

To Become a 255 Cr company by Implementing E commerce. In the process, we are committed to delight and respect our customers, employees, suppliers and communities.

The product range designed and fabricated by us are suitable for utilization in varied industrial sectors.

Pharmaceuticals

Food processing

Biotech and Medical industries

Plastic

Solar and Steel

Aerospace and Engineering industries

Textile

Drainage of soil and waste

"Innovation and product quality along with safety has been the USP of Ami Polymer"

— Alpesh .B. Gandhi

"Our Organization supports the growth of our employees through a management culture that encourages communication and training"

— Jigisha .A. Gandhi

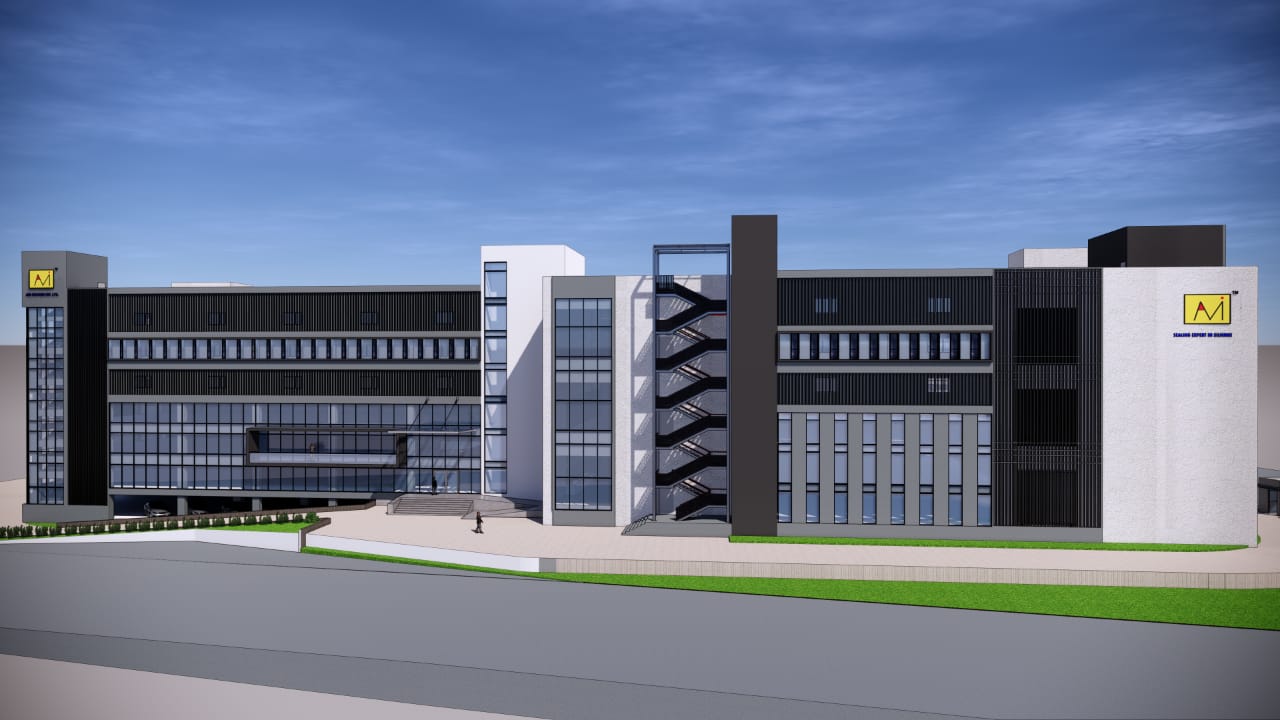

New Manufacturing Plant Construction. Our new manufacturing facility with 2,50,000 sq.ft. total area includes 60,000 square feet of total Cleanroom area, is under installation in Silvassa, India. The plant will be operational by 2023.