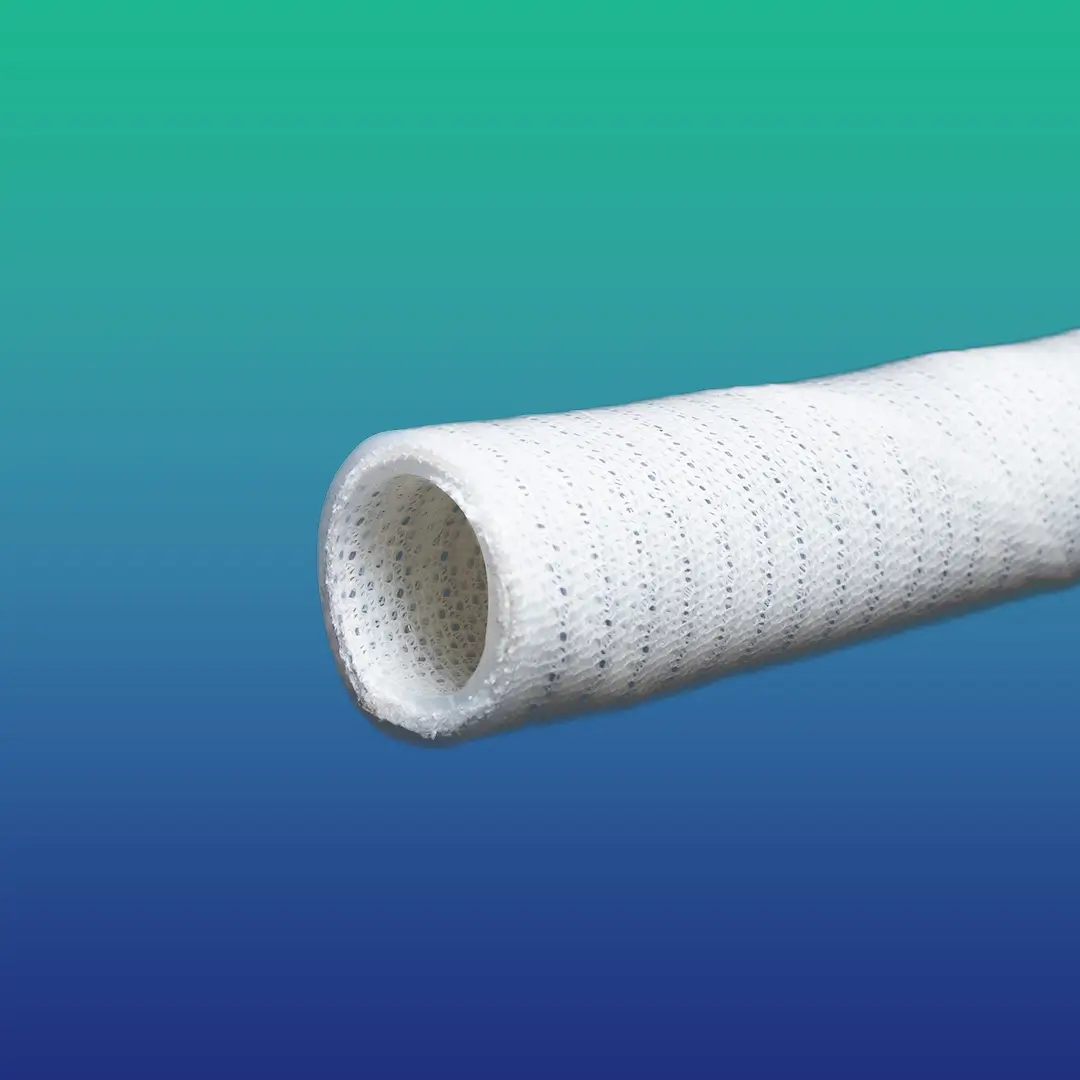

The Platinum Cured Silicone Mandrel Wrapped 4 Plies Fabric with SS Helical Wire Reinforced Hose is a sophisticated, high-performance industrial hose designed for applications requiring exceptional purity, durability, and flexibility. This hose is engineered to meet the rigorous standards of industries such as pharmaceuticals, biotechnology, food and beverage processing, and chemical manufacturing.

Key features

Menstruation or period, is normal vaginal bleeding that occurs as a part of a woman's monthly cycle. Every month body prepares for pregnancy. If pregnancy doesn't occur, the uterus or womb shed its lining.

4 Plies Fabric Reinforcement:

- Layers: The hose is reinforced with four layers of high-quality fabric, which enhances its strength, flexibility, and durability.

- Material: Typically, the fabric used is polyester or aramid, known for their high tensile strength and resistance to wear and tear.

SS Helical Wire Reinforcement:

- Material: The stainless steel (SS) wire provides additional reinforcement.

- Design: The wire is helical (spiral-shaped) and embedded within the hose structure.

- Function: This reinforcement prevents kinking, enhances pressure resistance, and allows the hose to maintain its shape under vacuum conditions.

Performance Characteristics:

- Temperature: Handles -80°F to 500°F.

- Chemical Resistant: No reaction with acids or solvents.

- Durable: Resists wear and high pressure.

- Flexible: Easy to handle and install.

- Hygienic: Maintains purity, sterilizable.

- Compliant: Meets FDA, biocompatible.

- Tough: Resists bursting, abrasion.

- Safe: Non-toxic, for food and medical use.

- Weatherproof: UV and ozone resistant.

Applications

The Platinum Cured Silicone Mandrel Wrapped 4 Plies Fabric with SS Helical Wire Reinforced Hose is particularly well-suited for:

Pharmaceuticals and Biopharmaceuticals:

- Transferring sensitive fluids like vaccines, drugs, and biologics.

- Handling sterile media, cell cultures, and pharmaceutical ingredients.

Food and Beverage Industry:

- Conveying food products such as dairy, beverages, sauces, and edible oils.

- Transporting ingredients in food processing and production.

Chemical Processing:

- Transfer of acids, alkalis, solvents, and aggressive chemicals safely.

- Handling corrosive substances in chemical manufacturing.

Medical Devices:

- Fluid transfer in medical equipment and devices.

- Use in sterile environments for medical applications.

Biotechnology:

- Handling bioreactors, fermentation processes, and biopharmaceutical production.

- Transferring bio-based materials and cultures.

Cosmetics and Personal Care:

- Conveying cosmetic ingredients like lotions, creams, and beauty products.

- Use in sanitary production of personal care items.

Laboratory and Research:

- Fluid transfer in laboratory equipment and setups.

- Handling chemicals, reagents, and samples in research environments.

Industrial Applications:

- Use in manufacturing processes requiring high-purity fluid transfer.

- Suitable for automation, machinery, and production lines.

Tri-Clamp (TC) Fittings:

- Design: TC fittings are designed for quick and secure connections in sanitary applications. They consist of two flanged ferrules (usually made of stainless steel) and a gasket, secured together with a clamp.

- Sanitary Connection: TC fittings ensure a smooth, crevice-free connection, minimizing the risk of contamination and allowing for easy cleaning and sterilization.

- Sizes: Available in various sizes to match the hose diameter and equipment connections, typically ranging from 1/2 inch to several inches in diameter.

- Materials: TC fittings are commonly made of high-grade stainless steel (such as 316L) for durability, corrosion resistance, and compatibility with sanitary standards.

- Gaskets: The gaskets used in TC fittings are often made of materials like silicone, EPDM, or PTFE, chosen for their chemical resistance and suitability for sanitary applications.

- Clamps: The clamps used with TC fittings are designed for easy assembly and disassembly.

Advantages of TC Fittings with the Hose:

- Ease of Installation: TC fittings allow for quick and straightforward installation without the need for specialized tools.

- Secure Connections: The clamp system ensures a tight and secure connection, minimizing the risk of leaks or contamination.

- Hygienic Design: The smooth, crevice-free connection provided by TC fittings is easy to clean and sterilize, meeting sanitary standards.

- Compatibility: TC fittings are compatible with a wide range of equipment and systems used in sanitary applications, providing versatility and ease of integration.

WHY CHOOSE APPL IMAWRAP HOSE ?

High Purity and Safety

- Platinum Cured Silicone: This curing process minimizes extractables and leachables, ensuring the highest level of purity. This is essential for applications in the pharmaceutical, biotech, and food and beverage industries where contamination must be avoided.

- Non-Toxic and Odorless: The materials used do not impart any taste or odor to the transported fluids, maintaining the integrity and safety of the product.

Exceptional Durability and Strength

- 4 Plies Fabric Reinforcement: Multiple layers of fabric provide superior strength and durability, allowing the hose to handle high pressures and frequent flexing without compromising its structural integrity.

- SS Helical Wire Reinforcement: The stainless steel wire adds extra support, preventing collapse under vacuum conditions and providing resistance against kinking and crushing. This makes the hose reliable for both pressure and suction applications.

Wide Temperature Range

- Extensive Temperature Tolerance: The hose operates effectively in a wide temperature range, from -60°C to +200°C (-76°F to +392°F). This makes it suitable for various applications involving extreme temperatures, such as steam transfer and hot air systems.

Chemical Resistance

- Inert Silicone Material: Silicone's natural resistance to a wide array of chemicals ensures compatibility with different fluids, reducing the risk of hose degradation and extending its service life.

Flexibility and Ease of Use

- Retains Flexibility: Even at low temperatures, the hose remains flexible, facilitating easy installation and maneuvering in tight or confined spaces. This reduces the effort and time required for setup and maintenance.

Compliance and Standards

- Regulatory Compliance: The hose meets stringent regulatory standards for industries such as pharmaceuticals and food processing, ensuring it is safe and suitable for use in these highly regulated environments.

Versatility

- Multiple Applications: The hose's robust construction and high-performance characteristics make it suitable for a wide range of applications, from transferring sensitive pharmaceutical ingredients to handling aggressive chemicals in industrial processes.

Cost-Effective

- Long Service Life: The durability and resistance to harsh conditions mean fewer replacements and repairs, leading to cost savings over time.

- Reduced Downtime: Reliable performance minimizes the risk of unexpected failures, reducing downtime and maintenance costs.

AVAILABLE SIZES

- Safety and Purity: Ensures contamination-free transfer of sensitive materials.

- Durability: Enhanced structural integrity for long-lasting performance.

- Temperature and Chemical Resistance: Suitable for extreme conditions and various chemicals.

- Flexibility: Easy to handle and install, even in complex setups.

- Regulatory Compliance: Meets industry standards for safety and quality.

- Versatility: Applicable across multiple industries and uses.

- Cost Savings: Long service life and reduced downtime contribute to overall cost-effectiveness.

Certification having on IMAWRAP Silicone Hose

- Conforms to US FDA 21 CFR 177.2600 Food grade Standard

- Conforms to USP Class VI

- Conforms to ISO 10993-1

- ROHS certified, free of restricted heavy metals

- Free of Phthalate/ Bisphenol/ Volatile Plasticizer.

- TSE/BSE Certification (free of animal derived material.)

- USFDA DMF accreditation #26201

- Complete Validation package available upon request

Leave a Reply

Your email address will not be published.