Understanding the "PUP SIT Assembly" in the Single-Use Biopharmaceutical Industry :

In the biopharmaceutical industry, it's important to have flexible, sterile, and efficient systems for moving fluids. One key part of single-use bioprocessing systems is the PUP SIT Assembly. While it may not be a common term, this assembly is crucial in keeping fluid transfers sterile and safe during processing.

What is PUP SIT Assembly?

The PUP SIT is a Pre Used Post Sterilised Integrity Testing assembly, used in single-use systems to transfer fluids, especially in the early and later stages of bioprocessing. It includes various parts designed to keep the process sterile and allow easy transfer of liquids without contamination.

Components of a PUP SIT Assembly

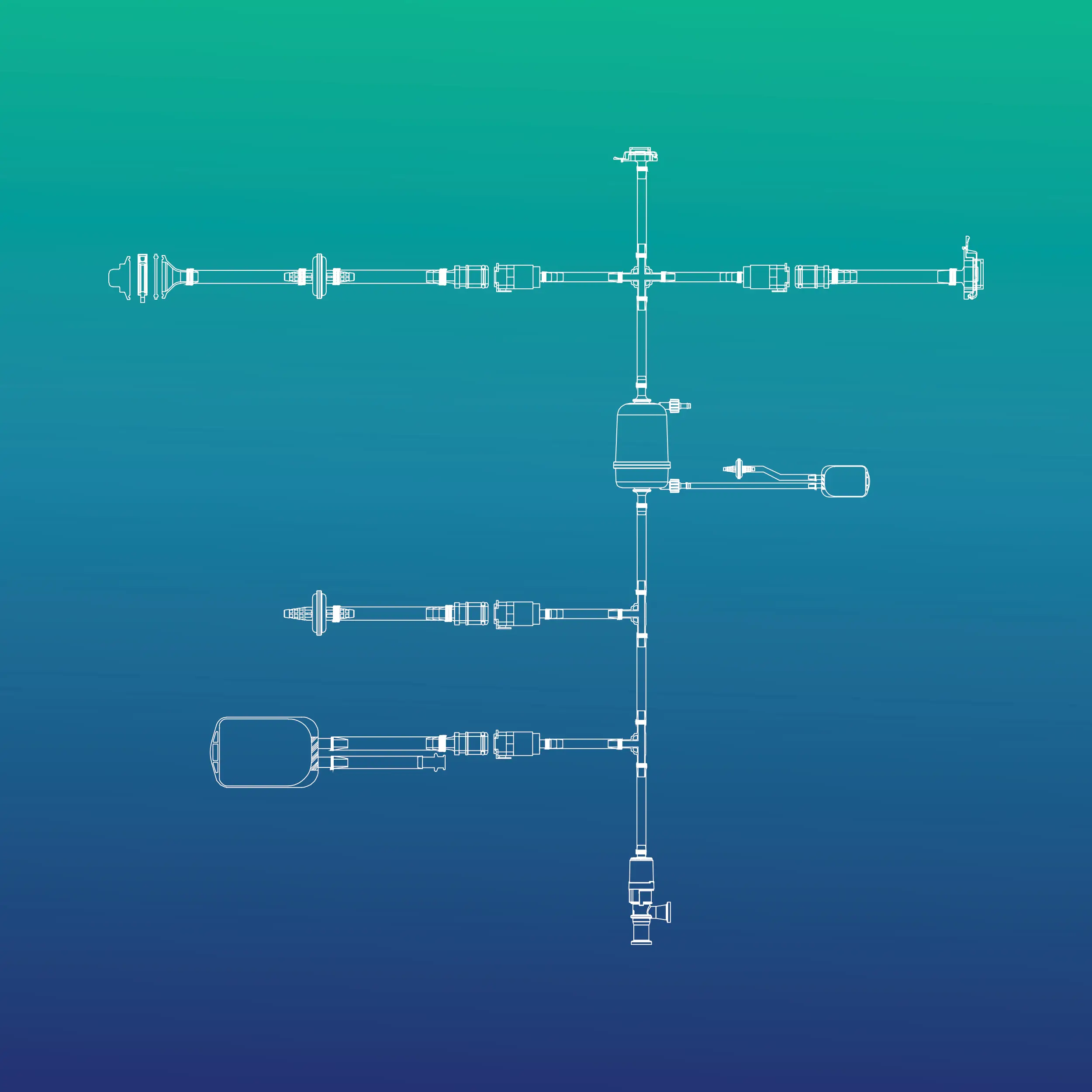

A PUP SIT Assembly consists of several main parts:

- Hoses and Tubing: Made from materials like silicone or special plastics, these hoses need to resist chemicals and meet biopharmaceutical standards. They come in different sizes based on how much fluid is being transferred. Tubing often has quick connectors to make the process easier and reduce contamination risk.

- Connectors: These are quick-connect systems like AQG, STC, or HFCD, which ensure a leak-proof and sterile connection. They are designed to easily connect or disconnect without needing welding or complicated fittings.

- Clamps: Stepless ear clamps are used to seal hoses or tubes securely, giving even pressure around the hose to avoid gaps and contamination.

- Filters (Optional): Some assemblies have filters to sterilize the fluids passing through.

- Overmolded Manifolds: These are included to reduce the number of joints, which minimizes leaks and contamination. They also have a smooth surface inside for easy cleaning.

Applications in Bioprocessing

The PUP SIT Assembly is used throughout different stages of processing, such as transferring media for cell culture or in the final steps of filtration and filling. Its main functions include:

- Sterile Transfer: Ensures safe and sterile movement of liquids without needing cleaning processes, saving time and reducing contamination risks.

- Modularity:The pre-assembled nature allows for quick connections, making processes more flexible.

- Scalability:These assemblies can be customized for both small-scale and large scale production.

Benefits of Using PUP SIT Assembly

- Sterility Assurance: Using pre-sterilized parts greatly reduces contamination risk, keeping the system sterile throughout fluid transfers.

- Efficiency: Single-use systems like the PUP SIT Assembly remove the need for cleaning between batches, making the process faster.

- Time-Saving: Pre-assembled components reduce setup time, important in high-production settings.

- Cost-Effective: By cutting down on cleaning, sterilization, and validation steps, single-use assemblies lower production costs.

- Process Flexibility: These assemblies can be tailored to different process needs, providing more design options.

Why Choose Ami Polymer's for PUP SIT Assembly?

At Ami Polymer, we proudly offer ISO Class VII and ISO Class VIII cleanroom facilities, certified to ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 27001:2013, and ISO 13485:2016 standards. Our products are supported by a comprehensive BPOG extractables program to meet regulatory requirements worldwide.

Founded in 1998, we are a leading manufacturer and supplier of single-use systems, specializing in bioprocessing bags produced in an ISO Class 7 cleanroom. Our manufacturing technology ensures world-class quality and end-to-end process capabilities to meet diverse customer needs.

Leave a Reply

Your email address will not be published.