Food and Pharmaceutical industries are facing many issues regarding safe processing operations. Major processing steps involved in drug manufacturing and delivery system are of having dynamic mechanical movements. Dynamic movement of machines generate static electricity charge on the surface of components. Silicone is most widely used polymer in pharma industries for fluid delivery and sealing application. Naturally Silicone rubber is having insulating properties in nature. Developed static electric charges on polymer surface can be reason of fire while contact with flammable processing solvents. Many fire incidents happened in last few years because of this reason.

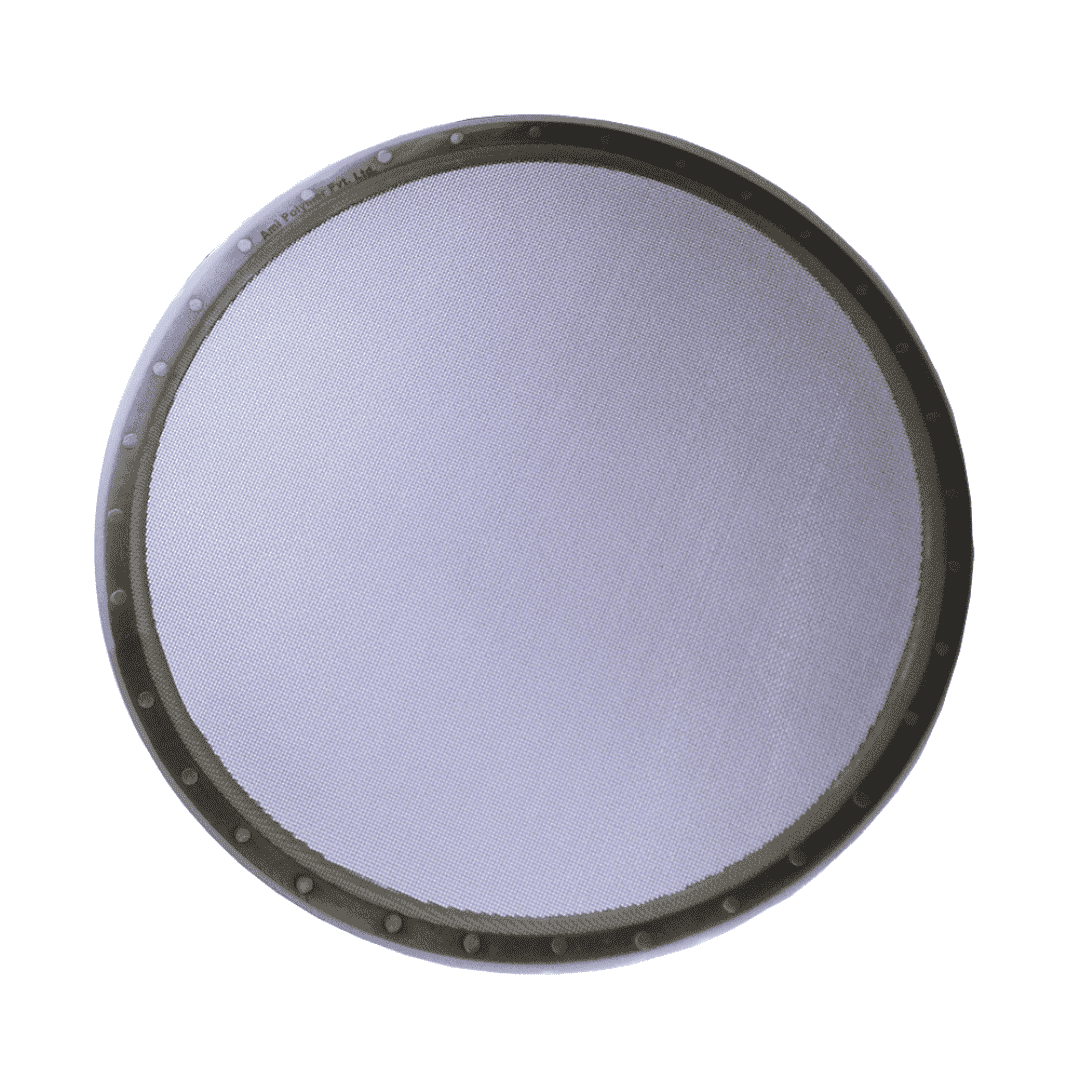

Our static dissipative is specially developed to dissipate static charge while sifting. Sieve are as technologically advanced in their designing, as they are brilliantly simplistic in their use. The silicone surface is left absolutely smooth and crevice free with its integrity intact. The complete sieve is turned into an Electro Static Dissipater thereby eliminating the fire, explosion and electrocution hazard.